Have you read the headlines of the wastage of COVID-19 vaccination while transporting it from labs to vaccination centers?

During the second pandemic wave, around 25% of vaccines were directly put into dustbins even before reaching doctors and patients. The biggest challenge was the lack of cold chain logistics infrastructure to transport vaccines requiring 2-8 degrees Celsius. Hence, India observed an escalated demand for cold-chain logistics infrastructure.

The dynamic environment has always demanded innovations in the Logistic Industry from time to time. Due to the lockdown, netizens were bound to fulfil most of the necessities by e-shopping. UNCTAD stated in a report that, “As lockdown became the new normal, the global retail share of ecommerce has surged from 14% in 2019 to 17% in 2020.” It led to the need for more logistics with innovative technologies.

Hence, the escalating acceptance of ecommerce is directly proportional to the need for modern logistics.

As Li Keqiang said, “Changes call for innovation, and innovation leads to progress”.` The innovation in the logistic industry developed in the past few years is connecting the world with improved supply chains. The technologies have left netizens’ jaws dropped with the latest trend in the logistic industry.

Hop on the latest trends of the logistic industry in 2022 and raise the bar of your company.

1. Last-Mile Delivery

As the name suggests, it is the last phase of the supply chain. It requires the utmost care and efficiency to achieve customer satisfaction. It is one of the most essential and critical parts of logistics as here the final product is delivered at the doorstep. It becomes the responsibility of the driver and logistics industry to use the best technology to deliver the product without any defect. Still, the last-mile delivery faces many challenges, such as delays due to traffic, customer nuances, government regulation, and delivery density.

Drones can be used to deliver goods and parcels to any part of the country almost without any defects. There is no need to waste fuel and energy in traffic congestion. It increases coordination from shipment to delivery and reduces cost. Smart Lockers secure the product from adverse weather conditions. It also vanishes the issue of customer unavailability as the product inside is safe. Hence the customers have the flexibility to receive parcels.

2. Blockchain

Documentation is one of the most vital functions of the Logistics industry. Hence, blockchain is a bane for the industry.

Blockchain is a digital ledger of duplicated transactions and distributed across the entire network of computer systems on the blockchain. In simple terms, all-digital ledgers are a series of encrypted “blocks” interlinked in a public chain.

If you buy a product in your area and a deal is made face-to-face, there is no trust issue. However, in interstate or global trade, the risk of forged and misleading documents exists.

There comes our savior BLOCKCHAIN!!

It builds a trustworthy environment for users by assuring 100% forgery and modification of free data, documents and transactions. The Blockchain in Trucking Alliance (BiTA) has around 85% of truck-based transactions in the world. Blockchain helps customers and suppliers track the visibility of the order. It increases efficiency and effectiveness by observing vehicle performance history.

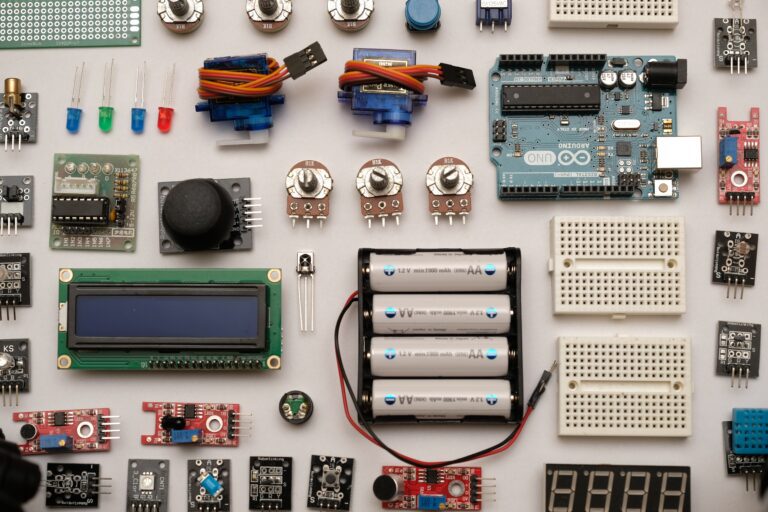

3. Internet Of Things(IoT)

Internet of things describes the network of physical objects -“things’- that are embedded with sensors, software, and other technologies to connect and exchange data with other devices and systems over the internet.

Companies are using IoT to enhance the logistics process. It improves security and theft detection by keeping an eagle eye on entrances in warehouses and missing product’s alerts.

For example, if someone steals a product or forgets to make payment, an alarm rings alerting the guards and automatically closing the doors.

This is how IoT works!!

It provides end to end product tracking. The employees get a higher level of security by detecting issues in machines or equipment before they use it. RFID tags and connected GPS sensors provide complete product visibility and hence also improves delivery. The managers can quickly analyze the number of items in the warehouse, its temperature, workers efficiency, factors affecting delivery, etc.

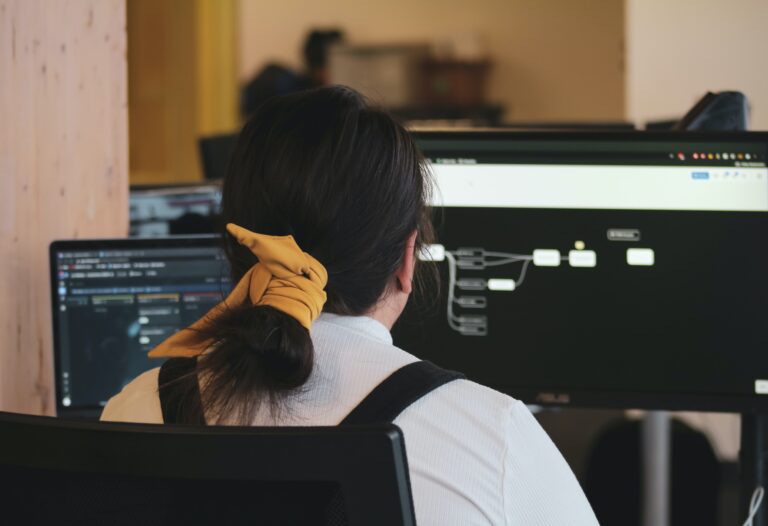

4. Big Data & Data Analytics

A good pool of analysed data is useful for enhancing warehouse productivity, performance management and optimal utilisation of logistical resources. The data collected from observing resources, weather and fleet schedules improve the routes and delivery planning. The ample data of markets helps optimise supplier pricing, inventory levels, and extract the risk management reports. The data is the prime ingredient of any company’s success.

For instance, a startup in the US named FACTIC provides a SaaS platform that offers predictive analytics solutions for the food and beverage industries. With its data mining and AI techniques, the startup analyses internal and external sources and predicts future sales. It also forecasts the gaps in demand and makes decisions based on the data-driven. With auto-replenishment, it offers tools to optimise stock.

5. Cloud Computing

The Cloud is used in virtually every aspect of modern life, including banking, email, media streaming, and ecommerce.

Microsoft defined cloud computing as the delivery of computing services- servers, storage, databases, networking, software, analytics and moreover the internet (the cloud).

Cloud computing is benefitting a lot of logistics service providers. In the logistic industry, daily interaction between stakeholders is necessary. Cloud computing enables the cost-effective connection of many partners throughout the supply chain. Besides this, the cloud-based SaaS solutions have the following advantage for logistics:

- Collects data from customers, retailers and wholesalers to comprehend the supply & demand gap.

- Easy to learn and has high adoption rates.

- Reduces the stress and cost of additional software with upgrading capabilities.

- The offered initial cost is also low.

- The business escalates to acquire a more extensive customer base.

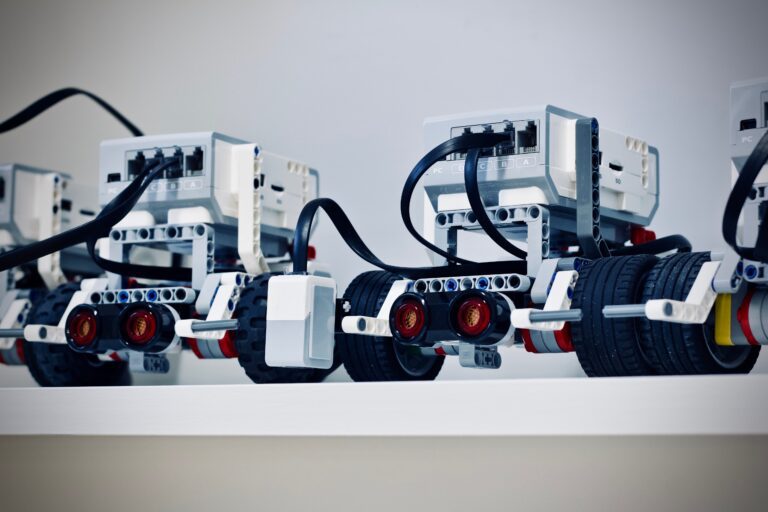

6. Robotics

In the modern world, the robot doesn’t require any definition; everyone knows it. The significant part is how robotics is bringing any change in the logistics industry?

Robotic Process Automation (RPA) has surged up in terms of development in the past few years. Robotic solutions based on advancing technology and affordability are aggressively entering logistics. Robots are famous in the logistic industry with functions such as pickup, distribution, and deliveries. A survey by EQDEPOT reveals that out of 32% of companies investing in technologies like automation and robotics, 40% want more robotics and 55 % want Enterprise Resource Planning Software.

By 2025, the global robotic market will reach $210 billion. Robots reduce human errors and thus bring an increase in delivery and profits. It allows workforce adaptability. It improves safety for workers by replacing them in risky jobs. It also brings uniformity in the packaging of products that are directly shipped to customers.

7. Automated Warehouse

The worldwide pandemic has given a push to the mindset of replacing human labor with the latest technology. Nowadays, companies favor mobile robots, advanced data analytics, and computer vision solutions to reduce human involvement.

Warehouse automation is the process of automating the transfer of inventory in or out of the warehouse to customers with less or no human involvement.

A French-based startup Exotec developed an automated robot Skypod which optimized the warehouse with more floor space and vertical space by using a vertical storage method. It provides a wide range of advantages to companies like:

- Better resource utilization.

- A decline in labor and operational cost.

- Better customer service

- Increased data accuracy & efficiency.

- Less shipping errors & inventory loss.

- More warehouse spaces.

Moreover, robotics and artificial intelligence play a vital role in the automation of the warehouse and logistics industry.

8. Autonomous Vehicles

The newspapers are daily flooded with the news of vehicle accidents. In this mishap, the foremost life of the driver and secondly the costly products get destroyed. That’s why autonomous vehicles are booming in the logistics industry.

As an example, Mars Auto is a South Korean startup that formed a vehicle software that offers driverless shipment transport. The AI-based software ensures a cakewalk delivery with tools like map the surroundings, control and complete guidance.

It eliminates human errors while driving and ensures the safety of both vehicles and products. The AI technology used in autonomous vehicles optimizes travel routes and reduces traffic jams. The fuel efficiency also improves with the platooning techniques. It boosts first and last-mile-delivery quality as they are designed to work 24*7.Asa

9. Elastic Logistics

Elastic logistics refers to a model of conducting business that is flexible and agile enough to upscale or downscale according to the demands of the market. Companies can handle the supply chain more efficiently in the period of high fluctuating demand with elastic logistics. The supply chain can be upscaled or downscaled as per the market demand. It helps to resolve the issues like underutilization of vessels, constraints on warehousing and overstocking.

Take the example of India-based startup GlassWing, which caters to on-demand freight transport with its various commercial vehicles. It has created a logistics service network and connects freight owners with transporters. It also offers real-time tracking, route optimization, freight security, customized reporting, and real-time alerts. It charges an affordable freight rate with the strengthened AI-enabled technology.

10. Digital Twins

Have a glimpse of Digital Twins’ magic in the logistic industry.

Many logistics professionals have said, the products and their computer models are never the same. Presently, modelling does not focus on how parts wear out and are replaced, how fatigue rises in structures, or how companies change and respond to the dynamic customer’s needs. Digital Twins are changing this picture forever.

Now you can see the blend of the physical and virtual world!!

This innovative technology helps you engage with the digital model of a physical object similar to how you do physical parts. It can be used in gathering products and packaging data which will bring the weakness and recurring trends to owners’ notice.

Hence, future operations will be improved. Even in warehouses, it can be used to make apt 3D models, experiment with designs or make new equipment and check their capability.

Related posts

- 5 Key Differences Between Supply Chain Management & Logistics

- Top 7 Supply Chain Risk Management Strategies

- 10 Best Third-Party Logistics (3PL) Companies In Chennai

- 7 Proven Ways To Improve Your Supply Chain Management (SCM)

- 7 Key Objectives Of Supply Chain Management (SCM)

- Top 10 Ways To Reduce Supply Chain Costs

- 9 Primary Benefits Of Supply Chain Management

- The Ultimate Guide To Supply Chain Risk Management

- 4 Major Benefits Of Blockchain In Supply Chain

- Only Technology Can Solve the Industrial Supply Chain Crisis

- Top 7 Supply Chain Management Challenges

- 8 Best Third-Party Logistics (3PL) Companies In Delhi

- Top 10 Latest Supply Chain Trends In 2024