B2B customer satisfaction is more difficult than ever; ask any parent who cannot purchase formula. Ultimately, all roads point to supply chain problems, whether a manufacturer lacking machinery parts or idle delivery trucks, warehouses with the wrong inventory, or cargo ships from flotillas. Bottlenecks define the supply chain and there is little hope that things will change any time soon.

Digital B2B eCommerce, while extraordinary, triggered the scope of the supply chain problem. Buyers purchase more online. This frictionless purchasing path has driven demand at a time when supply chains are fragile. Companies react to shortages by stockpiling supplies, exacerbating the misaligned inventory. These supply chain challenges are further aggravated by worker shortages found in every vertical segment.

Causes of global supply chain crisis

Disruptions around the world have led to shortages of industrial products. These issues cannot be traced to a single culprit. Resources are scarce, costs are up for everything from labor to transportation, and there is simply not enough capacity to meet demand.

One of the biggest drivers of supply chain disruptions and delays is the ongoing COVID pandemic. Port of Shanghai will not be fully operational until the end of the year.

Factors in the global supply chain create inflationary impacts; many economists are predicting a global recession this year. The war in Ukraine worsened the supply chain predictability.

During COVID, manufacturers cut costs and trimmed inventories reacting to weak demand. Now, faced with shortages, they are ordering extra supplies, increasing the strain on distribution systems.

Worker shortages are significant with unemployment at a fifty-year low and millions of unfilled jobs. The great resignation is omnipresent. It impacts the manufacturing sector and the entire supply chain, from dockworkers, warehouse staff, truck drivers, railyard workers, and maintenance specialists.

Only technology solves the Industrial supply chain crisis

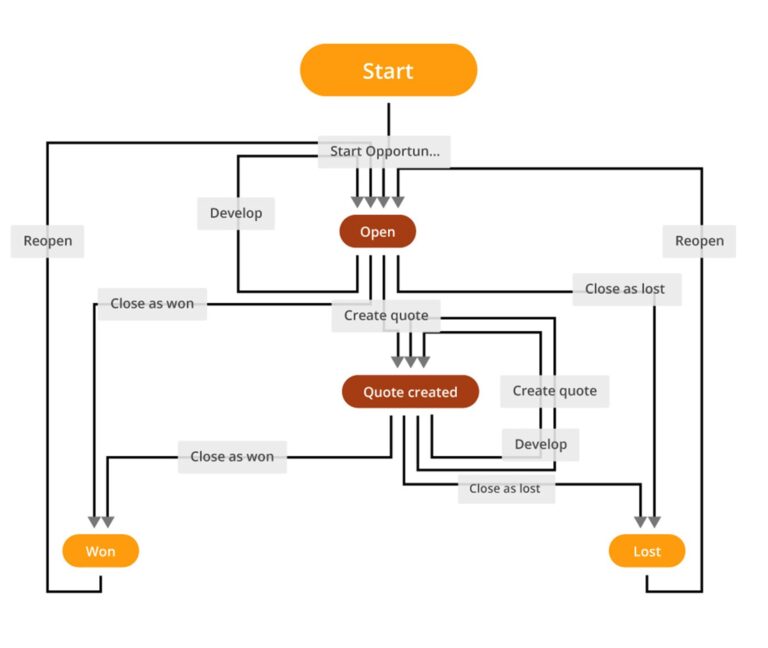

Supply chain conditions led many companies to rethink their supply chain operations. Digital technology promises and delivers innovation to an industry that needs it most. Only technology can help organizations build stronger, more resilient, and adaptable supply chains. The functionality of technology in the supply chain starts with spotting potential problems early.

The conditions plaguing the supply chain has driven a significant shift. Recently, most manufacturers and distributors primarily concerned themselves with efficient operations, monitoring, and reporting. Today, given the mercurial nature of the economy and geopolitical considerations, B2B businesses must continually monitor supply chains, spot upcoming disruptions on the horizon, and keep customers informed.

Supply chain monitoring tools: required for manufacturers, warehouses, and logistics companies

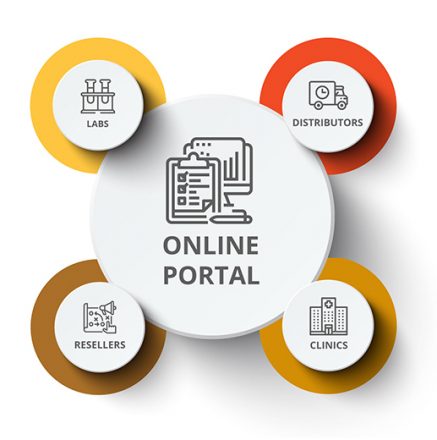

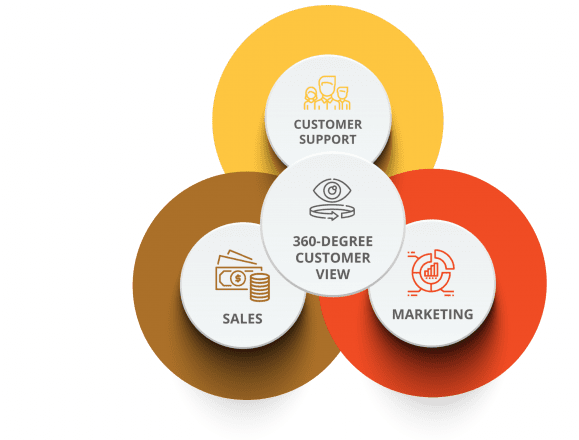

Successful companies are navigating the fluidity of the supply chain by integrating data between business systems including a B2B eCommerce platform, CRM, BI, and ERP. Integrated systems provide customers with insights into the supply chain before orders are placed. Only with increased information flows are businesses able to make informed decisions and apprise customers of real-time order status.

Enabling flexibility and agility

With supply chain challenges projected to last well into next year, now is a critical time to create supply chain flexibility. Digital solutions increase data visibility and allow informed sales projections that simultaneously consider various supply chain elements. Uncertainties in the market require quick sourcing abilities, capacity changes, and fulfillment flexibility.

Better customer experiences

Even before the pandemic, the customer experience was the key differentiator, more important than price. Companies that failed to pay attention to B2B customer experiences quickly learned during the pandemic that experience is very important to customers.

Delivering a better customer experience is the first step in integrating operations and segmenting processes. Supply chains play a massive role in customer satisfaction as it impacts the things that matter to customers: availability, price, and delivery times. When supply chain elements are out of control, it may feel helpless. Many powerful brands manage less-than-perfect supply chains and keep customers satisfied in these uncertain times.

The added transparency with suppliers enhances efficiency and responsiveness. It also helps manage inventory levels while minimizing planning cycle time. Visibility and agility are great, but businesses need the ability to act according to changing circumstances. Growing suppliers, boosting communications, making contingency plans, and expanding operations, generate a stable foundation for dynamic profitability regardless of supply chain limitations. A strong B2B eCommerce presence gives businesses greater maneuverability in the face of delays and disruptions than would a brick-and-mortar infrastructure.

B2B sellers: Prepare for continued supply chain difficulties

Supply chain issues are not going away in 2022, and perhaps not until 2024. Traditional responses such as diversifying suppliers, building alternative networks, and sourcing closer to home are not enough to keep goods flowing in the distribution pipeline.

Author Profile

Yoav Kutner is the Founder and CEO of Oro, Inc. Prior to founding Oro and building OroCommerce, OroCRM, and OroPlatform products, he was the CTO and Co-Founder of Magento, where he led product and technology development for all Magento offerings from inception until after its acquisition by eBay, Inc. in 2011. Yoav is a proven product visionary in the business application market. Yoav received a bachelor’s degree in Computer Science from UCLA.

Related posts

- 5 Key Differences Between Supply Chain Management & Logistics

- Top 11 Freight Forwarders In India [2024]

- 7 Proven Ways To Improve Your Supply Chain Management (SCM)

- The Complete Guide On In-House Logistics

- Guide To 3PL In Reverse Logistics

- What Is Customs Clearance?

- 7 Key Objectives Of Supply Chain Management (SCM)

- List Of 11 Best Logistics Companies In India

- Top 10 Logistics Trends To Look Out In 2024

- 7 Key Functions Of Logistics Company

- Top 10 Ways To Reduce Supply Chain Costs

- What Is Reverse Logistics?

- 9 Primary Benefits Of Supply Chain Management