The modern warehousing sector dramatically emphasizes the efficiency of storage and movement of materials inside and outside the warehouse. Pallets are one of the critical components designed to facilitate optimal storage and handling of goods. A ‘pallet’ is a rigid horizontal stage firmly fixed with a superstructure and a supporting deck at the bottom. Typically, a pallet acts as a base for containing one unit load of inventory at warehouses.

Pallets are rigid flat surfaces that have extensive load-bearing capacity and goods can be stored and handled in large numbers, ultimately creating efficiency in logistics and other in-house operations.

Pallets have been in use ever since warehouses were merely godowns. Let’s see how palletization transformed the complete warehousing scenario by incorporating different approaches to palletization.

Pallets have played a significant role over the years at warehouses by enabling stacking, storage, protection, and transportation of goods.

What is Palletization?

Palletization was said to be the smartest invention of the twentieth century after the barcode. The process of palletization simplified materials handling operations at warehouses in terms of both time and money.

Palletization showed businesses that it’s easier to move goods collectively on pallets, instead of carrying cartons or boxes individually.

The process of palletization is placing multiple goods (packaged or bulk) on pallets. Pallets are broad horizontal surfaces that have a high load-bearing capacity and facilitate stacking of products both horizontally and vertically.

Material handling equipment such as forklifts or pallet jacks is incorporated to facilitate smooth and efficient mobility of palletized goods within the warehouse and in transit.

“Pallets and the process of palletization are age-old concepts that came into existence over ten centuries back and have dramatic implications in the logistics and warehousing sectors even today.”

Approaches to Palletization

Even though palletizing goods is the most optimal process of carrying goods in bulk, there are different modes incorporated at warehouses depending on the nature of products that are shipped and dispatched.

Approaches to palletization are generally the methodologies used to stack goods on a pallet. There are three fundamental approaches to palletization.

Manual Palletization

Manual Palletization involves human workers to place goods on pallets as per requirement. Workers at warehouses play the role of carrying goods from the conveyor line and stacking them on pallets layer-by-layer.

These palletized goods can be stacked in the form of columns or in a staggered fashion, both of which are case-dependent and ensures sturdiness in a pallet. After the palletization of goods, material handling equipment such as pallet jacks or forklifts are used for the storage or transportation of goods.

Semi-Automatic Palletization

A warehouse deals with different types of goods and relying on manual labour leads to inefficiencies, primary injuries to the workers. The process involves the delivery of heavy goods on a conveyor to an ‘operator’. The operator uses material handling equipment to raise and land the goods as per the requirement.

This approach ensures that workers are safe and severe injuries are avoided. Semi-Automatic Palletization also increases the efficiency of storage and handling, as an automatic height lift table also has rotational features that offer even greater ergonomic benefits.

“Semi-Automatic Palletization only requires an operator to arrange goods layer-wise with mechanical equipment and save the energy and time invested in physical work.”

Automatic Palletization

Automatic palletization is the most technologically advanced method to carry out the palletization process. It is the fastest and most optimal way to stack goods on a pallet.

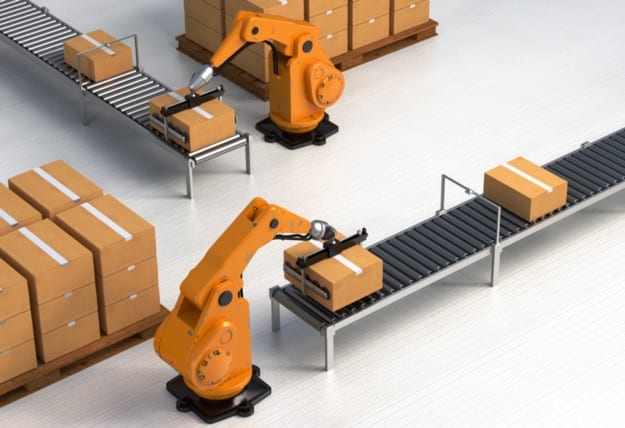

Automatic Palletization can be further categorized into conventional and robotic systems.

- Conventional System: These systems involve the transfer of goods through a conveyor belt, the conveyor belt delivers bulky products to the ‘layer building table’. The layer building table is pre-coded and innately follows a pattern that is in concordance with the code. This automatic equipment retrieves heavy goods and starts arranging them in layers and follows the same pattern repetitively. Automatic Palletization nullifies the scope for human error and has the potential of operating at different speeds that range from 10–200 cases per minute.

- Robotic Systems: This system is the futuristic method to palletize heavy or bulky goods. The robotic System involves the utilization of robotic arms that are equipped with ‘end effector’ (vacuum or clamp). These robotic arms are capable enough to lift goods from the conveyor belt and stack it on pallets appropriately. The Robotic System has become immensely popular for operations carried out under harsh environments — for instance, accumulating products in cold storages. Robotic System plays a significant role in ‘rainbow stacking’, which is typically incorporated in the beverage industry.

Why Palletize? Benefits of Palletization

Thousands of warehouses across the world are leveraging the benefits that come along with palletizing the goods. In such a competitive environment, pallets are an integral part of the warehousing sector. There are several key advantages that come along with palletizing your inventory.

Quicker Handling

The basic feature of palletization is the process of placing goods on pallets, this innate feature enhances the handling of goods at a warehouse. A single unit of palletized goods is known as a unit load, a unit load typically comprises of multiple goods stacked in layers. Carrying goods all at once in the form of several unit loads ensures faster handling. Also, perishable goods such as fruits and vegetables are handled and shipped optimally.

Optimized Functioning

Palletization plays a substantial role in the majority of the warehouses of today’s generation. The process of palletization has been an age-old discovery and the approaches towards palletization are inclining more towards the efficiency of operations. This shift is occurring by the inclusion of automated and semi-automated systems being introduced especially for palletization. Improvisation in the efficiency of ‘palletization’ is increasing the efficiency of other warehouse and logistics functions as well.

Reduced Risk

Palletization is also ensuring better safety of goods and especially bulky products. Many goods that are stored at a warehouse are heavy and valuable and contains higher risk due to damage or loss. Pallets are strong and flat surfaces that have a massive load-bearing capacity. Businesses can always be less worried about the safety of their goods if they are palletized.

Easier Transportation

Palletization reduces efforts in shipping and transporting goods. Since palletization allows multiple goods to be carried at once in multiple unit loads, it makes the transportation of goods much quicker, easier and hassle-free.

Pallet Racking

Pallet racking is a revolutionary phenomenon and has transformed the way you store palletized goods. Pallet racking is the process of storing palletized goods on a material handling structure known as a Pallet Rack. A pallet rack comprises of horizontal rows and vertical columns that facilitates efficient storage of palletized goods. ‘Pallet Racking’ ensures that the maximum number of goods are stored and maximum space is utilized.

Mobile Pallet Racking

Mobile Pallet Racking follows the same fundamentals of basic pallet racking, only here the pallet rack can be moved. Mobile Pallet Racking is an advanced way of optimizing the storage space in your warehouse. Mobile Pallet Racks serve the purpose of exploiting the unused space at your warehouse. These racks not only allows a warehouse to increase storage of palletized goods but also handle palletized goods more optimally.

Palletizing Robots

Innovation in palletizing has reached far until now and palletization is no more reliant on humans completely. Palletizers are robots that are designed to automate the process of stacking goods on pallets. Palletizers are a part of automated systems being incorporated at warehouses for palletization. Palletizers have the ability to operate at high speed which ranges from 10–200 cases per second and avoiding human error. Palletizers significantly increases the speed of palletization, that manual or semi-automated system cannot provide.

In a Nutshell…

Every warehouse in today’s generation is working with palletization as the key process. We at Stockarea are helping thousands of business all around India to store their inventory on Pallets and generate better ROI on their overall logistics costs. Get in touch with us and we will be more than happy to help you in finding the right warehouse partner to palletize and store your inventory.

Related posts

- 6 Major Advantages of Cold Storage

- 5 Core Functions Of Third-Party Logistics (3PL) Providers

- 10 Practical Tips To Reduce Warehouse Costs

- 11 Best Warehouse Management Systems (WMS)

- 4 Key Types Of Warehouse Management System (WMS)

- 10 Best Cold Storage Companies In India

- What Is Warehousing?

- Going Up: Logistics Leaders Solve Warehouse Space Constraints

- Top 10 Warehousing Companies In Chennai [2025 List]

- Top 10 Warehousing Companies In Kolkata [2025 List]

- Complete Guide On Dead Stock Inventory

- Cold Storage: Challenges & Opportunities

- 10 Types Of Pallets In Warehousing