Cold storage is a facility that primarily stores food items that are short-lived and highly likely to get spoilt under normal conditions. These may include fruits, vegetables, fish, meat etc. These food items are stored under optimum temperature(primarily low) and humid environment as required for individual items. Almost all cold storage rooms are designed such that these properties are pre-configured based on what is being stored. Some cold rooms are made such that these properties are adjustable.

Construction and Working of a Cold Storage Plant

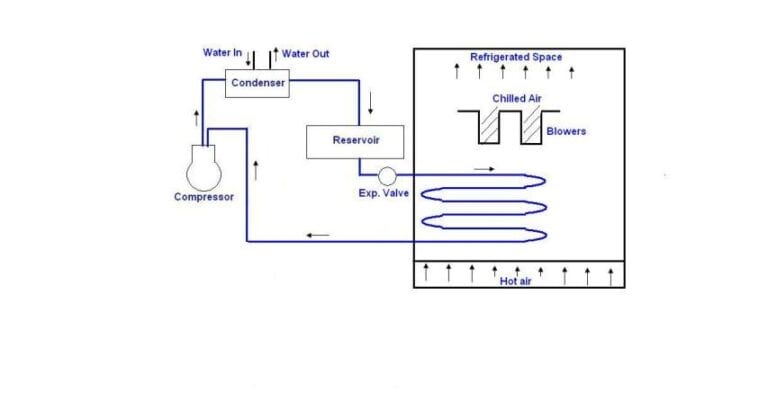

A cold-storage facility works on a refrigeration system which helps maintain an adequate temperature and environment as per the specifications of each item being stored. These are the main components of a cold storage room:

- Compressor – It is the main component that runs the cold room. It is the only device that needs the energy to run. The compressor consumes almost all the power in a cold room. It is used to raise the temperature and pressure of the refrigerant vapour coming out of the Evaporator. As the pressure is increased, the boiling point increases and the compressor can condense the refrigerant(for example, ammonia) at the temperature of the condenser.

- Condenser – It is required to remove the heat from the refrigerant and the circulating water. It carries out phase change of the condenser from gas to liquid at high temperature and pressure. The condenser acts as a heat sink, and its heat exchange efficiency determines the efficiency of the cold storage plant.

- Receiver – The high-pressure liquid condensate is stored here. It is here that the refrigerant comes after phase change from the condenser. After it has reached the receiver component, the liquid refrigerant goes to the expansion valve to decrease the temperature and pressure.

- Expansion Valve – It reduces the temperature and pressure of the refrigerant using a throttling device. The throttling process occurs through friction and there is a change in the temperature and pressure of the refrigerant. Its pressure changes from that in the Receiver to that in the Evaporator.

- Evaporator – The cyclic process that decreases the temperature of the items stored takes place here. It takes heat from the storage compartment or atmosphere that is supposed to be cooled. This heat is then used to vaporize the liquid refrigerant. This way, the food items are cooled and preserved.

- Blowers – The cooled air is spread across the room through the convection process, thus, achieving the desired temperature of the room.

In short, the refrigerant’s boiling point is reduced by increasing its temperature and pressure by the compressor. Heat is removed from the refrigerant as it is changed from gaseous to the liquid state by the condenser. Now the refrigerant is transferred to the reservoir for storage. Further, the refrigerant is moved to an expansion valve to reduce the temperature and pressure in the liquid state. The last step takes place in the Evaporator, where the heat from the surroundings is used to change the refrigerant again to a gaseous state, thus causing the cooling effect. The blower circulates this cool air.

Cold storage is essentially meant for storing items that need specific low-temperature surroundings. There is a misconception that cold rooms can store only food items this way. However, cold rooms can store the following items:

- Food Items – Several industries use cold storage services to preserve food items. Restaurants, food outlets, supermarkets and grocery shops are a few of these industries. These industries may require domestic fridges, entire cold rooms or blast freezers based on the type of item being stored and the customers’ needs. Blast freezers are needed to keep a large number of food items for long periods.

- Candles – In hot and humid climates, candles and similar items made of wax-like substances must be stored in a cold space. Melting will ruin these items and cause financial losses to the candle-making industries, raising the need for cold storage facilities.

- Films and Artwork – Film-makers can stop camera films from getting ruined by storing them in cold temperatures. Not all but many people still use this method when films need to be stored for longer periods. Old art pieces especially need controlled temperature in their storage spaces as the paint may start to peel off the canvas.

- Plants – Cold temperatures keep plants healthy, primarily decorative plants. Florists and ornamental flower companies especially need these facilities to store flowers whose stems have been cut.

- Cosmetics – Lipsticks, Mascaras, Nail paints etc., may get ruined in high temperatures due to melting at higher temperatures. Thus, while storing them for long durations, companies need to have optimum temperature in the warehouse.

- Pharmaceuticals – Pharmaceutical companies that deal with medicines use cold storage warehouses very often to store syrups, injections, etc. and protect them from denaturation. Cold temperature prevents them from getting ruined by contamination.

- Textiles – Textile companies that deal with organic cloth material such as fur, skin or wool always need cold storage facilities in their warehouse. This is because these materials can rot under high temperatures. It will make them unfit for use. Dry cleaners also make use of cold storage facilities.

- Refrigerated containers – It is the primary and efficient type of cold storage facility. They can be used for a small number of items that need optimum temperature storage. Further, workers can easily move them from one place to another.

- Blast Freezers and Chillers – These meet large storage requirements that need the items to be chilled when they reach the customer. High-end restaurants and similar companies use these.

- Cold rooms – These can be both refrigerants and blast freezers based on the requirement, except that they are much larger and in the form of entire rooms.

- Pharmaceutical grade cold storage warehouse – These are warehouses that have the cold storage technologies inbuilt with them. Used in hospitals and medical facilities, they are specially used to store blood, certain vaccines and biopharmaceuticals.

- Plant attached cold storage warehouse – When producers wish to keep the cold rooms within their factories, such facilities are built. Conveyor belts are used to send intermediary goods or finished products to cold storage. This makes it an on-site service.

- Dedicated custom cold storage warehouse facilities – It includes companies that have specific cold storage needs and need customized cold rooms. Instead of building entire cold rooms, they can get made one personally by 3PL logistic services or warehousing solution companies.

- Multiple variations

Most cold storage units have temperature-adjustable modes and are airtight as well. This protects the material inside from extreme temperature changes that may occur in the environment. Further, moisture content can also be regulated using a dehumidifier to dry out the surroundings as required. A cold storage unit can be converted to any of these from a cold room to a blast freezer. - All specifications are customizable

Each cold room can be built of a particular dimension and feature specification. Even the shape of a cold room can be customized. Based on what is to be stored, the correct refrigeration system can be chosen. Many times, a freezing temperature is not required for all goods. In such a case, a cold room can keep your goods cold and dry. Mobile cold rooms are also available now. - Acts as extra storage

Whenever space is not available for storing items in general, cold rooms themselves can be used. They keep almost all food items safe, and their temperature can be regulated along with the moisture. Items that especially need to be kept away from moisture can be stored here when the monsoon arrives. This way, whenever there are extra orders, the lack of space can be compensated. - It can be used for backup during a power outage

In case of power cuts, items stored in coolers and fridges can be moved to the cold storage area. This will prevent those items from getting ruined. The cold room will meet their optimum temperature requirement. The airtight nature helps maintain the cool environment for a longer duration. This will help keep the food items safely. Further, wire racks can be added, which will be kept empty if such a situation arises. - Reduction in waste saves money

As cold rooms preserve food items for long durations, they help in reducing wastage. This way, instead of unused goods being spoilt and thrown away, they can be stored for more time. Many restaurants preserve food after preparing it in frozen form; such a facility is provided through cold rooms. These are used when there is a supply crunch. This benefit also helps save the money that the company may have spent on buying extra items in place of the spoilt ones.

Problems associated with Cold Storage

- Negative impact on equipment and operator

Most cold rooms have adverse effects on the equipment placed inside. For example, as soon as a product will be removed from the cold room for palletization, it will gain moisture. This will spoil the product hence causing wastage anyway. Further, the person operating the cold rooms is often exposed to such artificial cold temperatures that harms their joints, bones, and overall health. Also, battery operated parts within a cold storage unit have extremely low power efficiency, reducing by almost 50% than at room temperature. In order to deal with these issues, palletization can be done within the cold room, and insulation kits can be provided to the workers of the cold room. Seals should be placed on batteries that make them resistant to extreme temperature changes. - Each good has different requirements

More than one product needs cold storage; however, each may not need the same temperature for storage. Moisture requirements will also differ for each kind of item. This creates an issue as a single temperature setting will be beneficial for only a few things. For example, vegetables need to be stored at 13°C, meat at -2°C, dairy products at 1°C and ice creams at -23°C. Thus all items don’t need to be frozen. Further, even the transportation requirements from the cold room may differ for each item. 3PL logistic services can be used to store different types of goods as they have such facilities. - They may be energy inefficient

Many studies have proven that cold storage facilities are often energy inefficient. This is caused even by the slightest error in insulation. Doors need to be of high quality, or the entire cold room may become ineffective. This means that there has to be minimal exposure to the outside environment. Only if these requirements are met can the cold room work well. Thus, well-built walls and doors preferably made of puff panels will help make the cold room energy efficient.

Frequently Asked Questions (FAQs)

Ans. The forklift needs to be of the accurate height for it to fit inside the cold room container. If this requirement is met, cold rooms have a structure sturdy enough to support the forklift’s weight.

Ans. Yes, you may contact your cold room provider for the changes you demand after the processing. They will be making the appropriate alterations to the cold room design.

Ans. Usually, 40ft containers hold 2360 cubic feet of items and 20ft containers hold 944 cubic feet. However, based on the needs, the space and shapes of cold rooms can be customized.

Ans. Yes, they can be made fireproof based on the customer’s demand.

Related posts

- 6 Major Advantages of Cold Storage

- 8 Best Practices in Managing a Cold Storage

- 6 Major Types of Cold Storage

- 10 Best Cold Storage Companies In India

- Cold Storage: Challenges & Opportunities

- Top 10 Warehousing Companies In Delhi

- Top 10 Freight Forwarders In Mumbai

- Four things to consider before buying a storage space in Pune

- Top 10 Transport Companies In India

- Top 12 Transport Management Softwares For Logistics Companies

- 4 Key Types Of Warehouse Management System (WMS)

- What Is Warehousing?

- Top 10 Warehousing Companies In Chennai [2025 List]